Introduction

Printed circuit board (PCB) assembly often faces significant challenges in efficiency and accuracy. Manual insertion of terminals and components is time-consuming and prone to human errors. Manufacturers frequently struggle with high defect rates, inconsistent output, and operator fatigue.

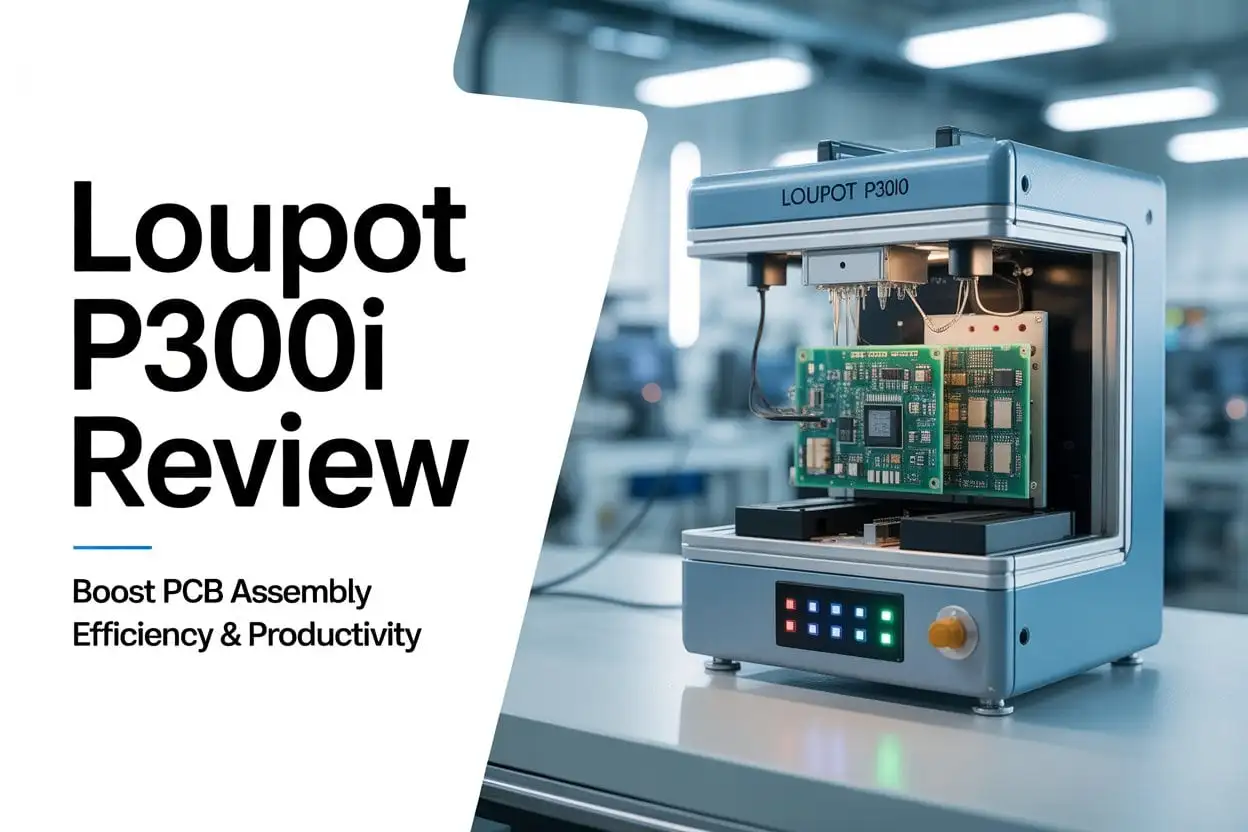

The Loupot P300i offers a practical solution for these issues. This semi-automatic insertion machine bridges the gap between fully manual and fully automated PCB assembly. It is designed to handle reeled or pre-formed terminals quickly and reliably, making mid-volume production more manageable.

In this review, we will explore the key features, benefits, and practical applications of the Loupot P300i. We will also discuss how it can improve efficiency, reduce costs, and deliver a strong return on investment (ROI). By the end, readers will understand why this machine is a smart choice for electronics manufacturing.

What is the Loupot P300i?

The Loupot P300i is a semi-automatic PCB insertion machine. It is designed to place terminals and components efficiently. Its primary purpose is to improve accuracy, reduce errors, and speed up mid-volume PCB assembly.

The “P300i” designation represents an improved version of the original P300 machine. The “i” often signifies “insertion” or “intelligent,” reflecting upgraded functionality and performance. This version is optimized for flexibility and reliability in electronics manufacturing.

Compared to manual insertion, the P300i significantly reduces operator fatigue and mistakes. Operators can handle more boards in less time while maintaining consistent quality. In contrast to fully automated machines, it offers easier setup, lower cost, and smaller factory footprint. Therefore, it is ideal for manufacturers seeking a balance between efficiency and flexibility.

In short, the Loupot P300i bridges manual labor and full automation, providing practical benefits for modern PCB production.

Key Features & Technical Specifications

The Loupot P300i delivers impressive performance in mid-volume PCB assembly. It can achieve insertion rates of up to 7,200 terminals per hour, depending on board complexity. The machine supports reel capacities ranging from 5,000 to 20,000 units, ensuring long, uninterrupted production runs. Its operational speed balances efficiency with accuracy, reducing errors and rework.

Equipped with PLC or PC-controlled systems, the P300i integrates smoothly with Manufacturing Execution Systems (MES). This allows real-time monitoring of production, ensuring traceability and quality control. Operators can program insertion sequences, monitor performance, and adjust parameters quickly.

The machine features a clinching system and insertion detection, which secure terminals under the PCB. These systems also monitor insertion force, preventing damage and improving consistency. Together, they enhance reliability and reduce scrap.

Additionally, the P300i has a compact footprint, making it suitable for smaller production lines. Its tooling flexibility allows quick changeovers and adaptation to different terminal types. This combination of precision, speed, and adaptability makes it a highly efficient solution for electronics manufacturers.

Benefits of Using Loupot P300i

The Loupot P300i significantly increases productivity in PCB assembly lines. By automating terminal insertion, it reduces cycle times and accelerates production. Manufacturers can complete more boards in less time, improving overall efficiency.

Operator fatigue is greatly reduced, as the machine handles repetitive tasks automatically. This also lowers the risk of human errors, resulting in higher-quality assemblies. Consistent insertion ensures fewer defects and less rework, saving time and resources.

The P300i offers exceptional flexibility for small-to-medium volume production. Its quick tooling changes allow easy adaptation to different boards or terminal types. This makes it ideal for mixed-production lines, prototyping, or seasonal runs.

Compared to fully automated insertion lines, the P300i is highly cost-effective. It requires lower initial investment, occupies less floor space, and still delivers high efficiency. Manufacturers can achieve a strong return on investment without committing to expensive, high-volume systems.

Overall, the Loupot P300i balances speed, quality, and flexibility, making it a smart choice for modern electronics manufacturers.

Practical Applications & Use Cases

The Loupot P300i is ideal for mid-volume PCB assembly. It handles thousands of terminals per hour reliably. Manufacturers can process moderate production batches efficiently without sacrificing quality.

For prototype and development runs, the P300i offers unmatched flexibility. Quick tooling changes allow engineers to test different designs rapidly. This reduces waste and accelerates time-to-market for new products.

In hybrid or high-volume production lines, the machine can serve as a support unit. It manages less critical insertion tasks or specific terminal types. This frees up fully automated lines for primary operations, improving overall workflow.

Overall, the P300i adapts to various manufacturing needs. From small prototyping to mid-scale production and hybrid support, it ensures consistent performance and efficiency. Its versatility makes it a valuable asset for electronics manufacturers of all sizes.

Strengths & Limitations

The Loupot P300i offers several key advantages for PCB assembly. First, it significantly boosts productivity compared to manual insertion. Operators can complete more boards in less time while maintaining consistent quality.

Its flexibility is another major strength. Quick tooling changes allow adaptation to different terminal types and board designs. Combined with quality features like insertion detection and clinching systems, it ensures reliable and accurate assembly.

However, the P300i is not fully automated. Some operator input is still required, which may slow extremely high-volume production. Additionally, tooling costs and setup time can impact short production runs. Manufacturers must plan for these factors to maximize efficiency.

The machine performs best in mid-volume or mixed-production scenarios, prototyping, and hybrid lines. When used in these contexts, it delivers maximum ROI, balancing speed, cost, and quality for electronics manufacturers.

Buying Guide & Considerations

When purchasing the Loupot P300i, start with insertion requirements. Ensure the machine supports your terminal types, board sizes, and reel capacities. Compatibility is crucial for smooth PCB assembly and minimal downtime.

Next, consider changeover and setup needs. Quick tooling changes improve flexibility, but some setups require time and careful planning. Also, verify that your factory has adequate power supply, air pressure, and floor space to accommodate the machine.

Maintenance and vendor support are equally important. Check for local availability of spare parts, tooling services, and technical assistance. Reliable support ensures minimal disruptions and consistent production performance.

Finally, evaluate the Total Cost of Ownership (TCO). Include the purchase price, tooling, labor, maintenance, and potential downtime. Compare these costs with expected ROI from increased throughput, reduced errors, and improved efficiency.

By considering these factors, manufacturers can make an informed decision and maximize value from the P300i.

Comparison With Other Insertion Machines

Insertion machines vary widely in automation, cost, and flexibility. Understanding the differences helps manufacturers choose wisely.

Manual insertion is highly flexible and requires low capital. However, it is slow, labor-intensive, and prone to errors. This approach suits very small runs or prototyping but limits throughput.

Fully automated insertion lines offer maximum speed and consistent quality. They are ideal for high-volume production with minimal variation. However, they involve high upfront costs, complex setup, and less flexibility for small batches.

The Loupot P300i fits between these extremes. It is a semi-automatic machine that balances cost, flexibility, and productivity. It is faster and more reliable than manual methods, yet less expensive and easier to manage than full automation.

Overall, the P300i is best for mid-volume runs, mixed-production lines, and hybrid workflows, providing manufacturers a practical, cost-effective solution.

FAQs About Loupot P300i

Q1: What are the typical insertion rates?

The P300i can achieve up to 7,200 insertions per hour, depending on terminals. Operator speed and board complexity also influence actual performance.

Q2: Is it compatible with all terminal types?

The machine handles reeled or pre-formed terminals. Always verify dimensions, reel size, and clinching requirements for your boards.

Q3: How much floor space and utilities are required?

The P300i has a compact footprint of roughly 490 × 480 × 480 mm. It requires 220V AC power and minimum 5.5 bar air supply.

Q4: Is it suitable for different production volumes?

Yes, it works best for small-to-medium runs, prototyping, and hybrid production lines. Very high-volume lines may need full automation.

These FAQs clarify the machine’s capabilities and ensure manufacturers make informed decisions. It balances productivity, flexibility, and cost-effectiveness for various PCB assembly needs.

Conclusion

The Loupot P300i offers significant benefits for PCB assembly. It improves productivity, reduces errors, and ensures consistent quality. Its semi-automatic design balances speed with operator flexibility, making it ideal for mid-volume production.

Manufacturers can use the P300i for prototyping, hybrid production, and small-to-medium runs. Quick tooling changes and flexible operation make it a versatile solution. Additionally, its compact footprint and cost-effectiveness deliver a strong return on investment.

If you are evaluating PCB insertion solutions, consider the Loupot P300i carefully. Check specifications, run test insertions, and calculate expected ROI. Doing so ensures the machine aligns with your production needs, improves workflow efficiency, and reduces overall costs.

In short, the P300i is a smart choice for electronics manufacturers seeking reliable, flexible, and efficient PCB assembly.